How we proceeded ?

At the beginning we thought it would be simple. We planned to equip the beta-testers approximately at the same time, leave them the ORTHOPUS Supporter for 1 month and gather their feedback.

Spoiler alert : it didn’t go as planned (as always 😉)

👎 Our flops :

- Our beta tester’s identification strategy

To lead a successful beta-test, it’s better that the device fits to the tester’s needs. To confirm our selection we asked our users to check the device’s relevance with their occupational therapist and after this, we met and exchanged with them by videoconference. But it’s quite impossible to be sure that a technical aid for the upper limb is useful and adapted to someone, based on a few questions and a paper written assessment. Ideally, we should have included occupational therapists used to equipping the upper limb with technical aids and schedule appointments at the user’s home at the very beginning.

In the end, out of 5 ORTHOPUS Supporter’s beta-testers :

– 1 person returned his device after 15 days : the person had enough mobility and didn’t need it to move, the device stood more in its way than it helped him

– 1 person uses it daily, particularly to eat

– 1 person uses it occasionally, to move his arm, to play for example

– 2 persons need an arm brace that offers more support for the arm and more support on the horizontal plan, which could correspond to our next product.

- Asking for the wheelchair’s specification to late

The ORTHOPUS Supporter is easily adjustable on an electric wheelchair. But it sometimes becomes complicated when the arm rest isn’t the chair’s original one or if there is no electric connection available at the back of the wheelchair (it proved that installing medical devices is a respectable job 😊). The individual and specific adaptations have made us go back and forth, visiting our testers and ordering specific items. Which resulted in several delay weeks before we obtained, ready for the test and functional devices.

- Overestimating survey to collect data

In order to gather feedback from our users during the test, we prepared a log book that they could fill in, on paper or online. But it didn’t work. At all. We realized it was a not so fun task and came with a mental load for our users or their helpers, during the day. More fluid and personal were the photos and video exchanges spontaneously.

- Going out big to call out for beta testers

How do we proceed to find users eager to test our solutions? We attempted a simple method : the online call out. Thanks to all the people who shared it on social media (specifically themed facebook groups), we received more than 50 applications in less than a week !

- 2 steps process

Before starting the beta-test, we worked with alpha testers. For the ORTHOPUS Supporter we worked with Pierre : we developed the prototype with him throughout several appointments at the ESEAN AFP France Handicap, healthcare facility based in Nantes. It permitted us to build a functional version of the ORTHOPUS Supporter. Then we equipped our beta testers with this version. It confirmed our desire to work with several alpha testers for the next prototypes.

- Meeting our users

It is surely the most interesting and exciting part about the organization of a beta test. The participating members trusted us, welcomed us in their homes, with their helpers and family. These are privileged and unique moments between the engineers developing the device and the people needing and using it on a daily basis. Beyond the feedback about the product, the discussions and the people taught us a lot about their feelings about technical aids, about life with a motor disability, their ideas, frustrations and dreams. We dearly thank every single one of them for sharing all that with us.

The feedback about the ORTHOPUS Supporter

Simultaneously with the beta-test, we have collected several dozens of advice, opinions, remarks from professionals and users on the occasion of fairs and demos in healthcare facilities. And to have a full report, we also conducted a use test with the CoWork’Hit, CMRRF Kerpape’s innovation center, with 8 patients and 6 occupational therapists.

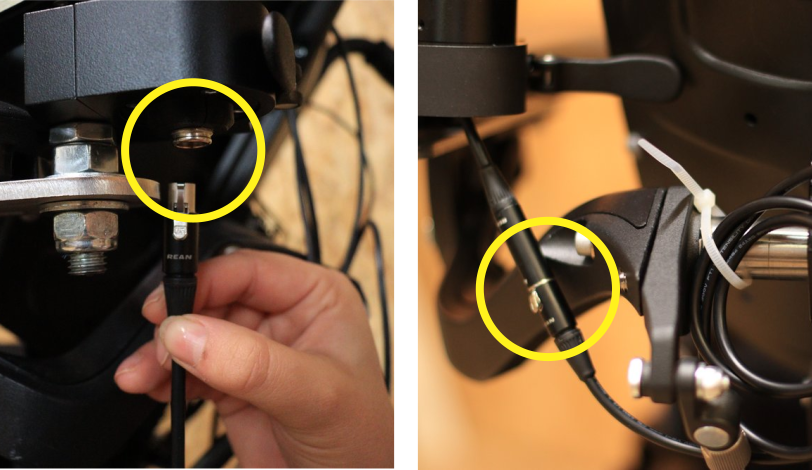

As an answer to the feedback we gathered we did some mechanical changes. Such as a simplification of electrical connections and the addition of the keyed connection on the arm brace’s screw. The remote control is now delivered with a separable base, our users can use the 2 buttons together or install them separately, fitting their hand mobility.

Regarding the software function, we simplified the access to settings and preferences with the rear button at the back of the device (colors, pressions etc).

Focus on the arm brace

The arm braces furnished by manufacturers will always be standard, even if there are different sizes available. But some people might need more and custom-made support. In this case, it is possible to reach out to an ortho-prosthetist to adapt the arm brace : it has been done for one of our beta testers and the result was more than satisfying !

Conclusion

During the development process of an assistive device, the co-conception with users requires time and to be ready to try different procedures you may have to adapt during the trial.But to us, it is necessary, inescapable, to offer useful and pertinent products to assist users everyday.

We were taught a lot during this first beta test and will only improve our methods for the next products. We are passionate about finding new ways to include our users even more! Assistive device manufacturers: how do you do to test your devices during their development? What success and failures did you face? Let’s share our ideas to get better together.